The Right Kind of Testing Makes It Easier

How do you solve a toy puzzle? Do you look for patterns as you put the puzzle pieces together? Do you start with the outside and work your way in? We all have our preferences but without ALL the pieces of the puzzle, how do you expect to finish it? We know what the puzzle will look like, it’s printed on the box! But not all puzzles are the same. That is, we are not provided a picture of the completed puzzle so we have to rely on our training and the assets at hand to solve the puzzle; we need to work smarter.

When a subscriber orders broadband services from an operator, such as ADSL2+ or VDSL2, it’s expected that technicians have the necessary training, tools, and test gear in hand to complete the puzzle. If one or more of these is missing or lacking, however, it becomes much harder to complete the installation or repair job in a timely manner due to that missing piece of the puzzle. Just as technicians have become good at the installation and repair of ADSL2+ and VDSL2 circuits and services, and installation and repair times have gone down,

the industry has introduced a new technology — and this means a new set of puzzle pieces.

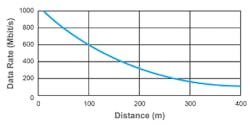

Figure 1. Aggregate G.fast Data Rate

The new technology kid on the ultra-broadband block is G.fast or ITU-T "G" Series recommendation for fast access to subscriber terminals (G.9700 and G.9701). G.fast can offer substantially higher data rates to subscribers than VDSL2 single pair or even VDSL2 bonding. (See Figure 1.) G.fast can offer aggregate data rates of up to 1 Gbit/s which makes it a very competitive solution for operators to offer to subscribers with the benefit of lower capital expenditures (CapEx) than doing a fork-lift upgrade of the last mile of copper to solely deploy fiber-to-the-home (FTTH). With new services coming to subscribers living rooms like 4k UHD TV via IPTV or over-the-top (OTT) deployments, the need to boost the speed of the physical layer and G.fast is a perfect complement for these new services.

G.fast can be tailored in such a way that an operator can configure the bandwidth being used. Unlike its DSL predecessors of ADSL2+ and VDSL2, which use Frequency Division Duplexing (FDD) to separate what frequencies upstream can use and which frequencies downstream can use, G.fast uses Time Division Duplexing (TDD) so it has access to the full operating spectrum. G.fast can operate from 2.2 MHz to 106 MHz, allowing it to coexist with ADSL1/2/2+ deployments. Alternatively, it can operate from 17 MHz (or 23 MHz) to 106 MHz to coexist with VDSL2. This range in bandwidth puts G.fast in contention with other radio frequency (RF) interferers such as amateur radio, terrestrial television (Channel 2 to 6 from 54 to 88 MHz) and FM radio (87.5 to 108.0 MHz). This is really no different than ADSL2+/VDSL2 sharing bandwidth with AM radio (535 to 1700 kHz).

Although loop lengths are shorter with G.fast (deployments from 20 m to 400 m) than with VDSL2 (900 m to 1200 m typical), there is the potential for the same faults to appear on the copper circuit. Bad splices, wet splices, split pairs, bridged taps, impact from impulse noise, crosstalk, and such, can happen. These faults will impede the data rates being offered to subscribers, and can also negatively affect the services deployed resulting in a poor quality of experience. Equipping technicians with the right tools is essential to ensure they can collect all the pieces of the puzzle and get the services up and running in a timely fashion.

Since G.fast is new, all eyes will be on subscriber quality of service and experience and hence operators have to be prepared ahead of time. What’s more, operators will not simply replace existing ADSL2+ and VDSL2 circuits with G.fast overnight, yet the technician will be required to install and repair all these circuits. The best tool to support the technician would therefore be a single solution that supports both ADSL2+/VDSL2 and G.fast.

One smart and efficient way to get all the pieces of the puzzle, and see the complete picture when testing, is by using automated test scripts. Traditionally, technicians may have relied on their trusty voltage and capacitance meter and/or resistance meter test sets to verify quality of a circuit. Although these are essential measurements even for VDSL2 and G.fast, there are more tests needed to truly understand this outside plant environment; these include time domain reflectometry, corrosion/wet detection, and metallic insulation resistance to 1 Gohm. Moreover, when performing these tests, is the technician confident enough to interpret the results? Confident enough to act upon the results to correct a problem situation? A solution that can instill confidence through on-board analysis of the automated test sequence will greatly aid technicians in their day-to-day installation and repair jobs — novice and seasoned technicians alike.

Automated testing by emulating the customers experience over G.fast is essential too. As mentioned earlier, technicians will not be dispatched ONLY for G.fast, they will have jobs requiring VDSL2-17a, ADSL2+, or VDSL2-35b, installation too, so a solution offering all these technologies is key for the technician in the field. The technician will be able to get to the distribution point unit (DPU) or digital subscriber line access multiplexer (DSLAM) and see what the negotiated data rates are, how much wiggle room there is via the signal-to-noise information, and then test the services the customer is expecting such as Internet, IPTV, and VoIP. With respect to IPTV and VoIP, these technologies use UDP protocol which means ensuring a fault-free physical cable as well as a fault-free G.fast connection is mandatory — subscribers will see or hear impairments and will ultimately complain about the poor quality of experience.

By solving the puzzle — and learning through constructive feedback — the job of installing, troubleshooting and repairing G.fast circuits or any other voice or ADSL2+/VDSL2 circuit for that matter, will improve the confidence of the technician in the field. In turn, with positive customer service experience, the subscriber will have confidence in the services you are providing.

[toggle title=”7 Puzzle Solving Tips” load=”hide”]

Employ these 7 tips to succeed in installing and deploying G.fast (or VDSL2).

1. Segmenting the network narrows down fault location(s), and greatly improves the success rate when

troubleshooting the installation or repair.

2. Complete the puzzle using automated copper test scripts or closeout tests that can both provide clear

feedback to all technicians no matter their skill level and instill confidence.

3. Complete automated G.fast (or VDSL2) test scripts or closeout tests to validate data rates, signal-to-noise ratio, and no errors. Confirm services such as IPTV and VOIP are up and running over the established link.

4. Collect test results from the field and learn from these results (analytics); is your network in good health?

Do you need to allocate human and equipment resources to a particular area? Correlation between copper closeout tests and DSL closeout tests is vital for learning the relationship between copper health and

DSL performance.

5. Manage your fleet of test sets. Cloud-based solutions can ensure all units have the latest software on them and you can push general or specific test profiles/configurations to them to ensure compliance to your company’s processes.

6. When automated test scripts report a fail, ensure your G.fast test equipment has additional copper test and measurement tools onboard to be able to locate faults and improve understanding of what you are dealing with. Measurements such metallic insulation resistance test with voltages up to 500V (very important in case of remote powering of the DPU), stressed balance, resistance fault location (RFL), and time domain reflectometry (TDR) are just a few additional measurements that are very useful to the technician.

7. Take your time, do it right. The saying "measure twice, cut once" applies perfectly.[/toggle]