But How?

For telecommunications companies, the pace of the technology evolution following the invention of the Personal Computer has been a moving target. More than ever, business and consumers are online, connected and data driven. The data pipeline provided to a large business several years ago would not meet the needs of a socially awkward teenager today. The need now is to connect people, businesses, and devices to high speed data services at all times in all places.

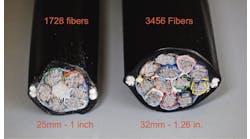

This has forced telecommunications providers to increase data transmission capacity not only between switching and data centers, but all the way to the user. When it comes to maximizing data throughput, the medium of choice is fiber. The data centric network demands fiber and lots of it.

Efficient fiber cable placement requires a skilled and well-trained work force. Therefore, training and process automation are the keys to success.

Figure 1a. Directional drilling using GIS.

Training and Training Components

An outside plant (OSP) project starts with design and engineering. To meet the market need, ICT providers today should find a trusted partner that has an in-house engineering model that utilizes global talent and cost-reduction methods, and also allows for rapid response and scalability across a broad array of projects.

5 criteria providers should consider when looking for that trusted partner include:

Criteria #1

Someone who has an understanding that architecture design parameters can be very different from customer to customer. These differences can be slight or large, in either case a complete understanding of these requirements must be understood by the engineering design groups. This is not an easy task when engineering is off-shored. Upfront training of design teams is a must. To insure designs, meet the customer design parameters a quality process puts in place.

Figure 1b. Directional drilling screen.

Criteria #2

Someone who understands that permitting, municipal requirements, can easily be underestimated. Not having done the proper research and communications with the local agencies can cause long delays, re-work and poor relationships, that can ultimately cause delays. Each municipality may have different requirements that need to be fully understood and taken into consideration.

Criteria #3

Someone who understands that national standards, such as the NESC, are important to fully understanding the implications of plant placement and the rules to abide by during deployment. It’s required to work through agreements with other utilities when attaching to pole structures. Understanding the NESC rules will help determine what is practical and allowable under the current standards.

Criteria #4

Someone who knows that utility agreements from telecom and power utilities must be obtained before attaching their structures. It is important in lecture-led training to have open communications with them to understand the rules and requirements. Working closely with the utility companies will help in the deployment progress and eliminate roadblocks. Specific working agreements with communities goes along with permitting, but sometimes along with obtaining permits it helps to work with the communities to reduce tensions and unforeseen issues down the road that could have been prevented. Communities want to know that you care and respect their community.

Figure 2. Below Grade application.

Criteria #5

A partner that can deliver equipment training that consists of a boot camp inclusive of computer simulator and hands-on field training. Training components should be specific to the area of specialty. For example, OSP training should be focused on safety, installation processes, equipment operation, and behaviors.

Governance should be in place to ensure persons assigned into a project have training appropriate to the project and their roles. If, for example, a project requires transit authority training for track crossings, that should be identified as mandatory for the student slated for that project.

Adjustments to the approach should be made based on student feedback and analytics collected during the training. Some classes should have web-based learning (WBL) as a prerequisite to help persons coming into OSP construction for the first time so they learn the terminology and industry basics at their own pace before they start instructor-led training. This will help improve the student-instructor dialogue during lecture-led training. This baseline knowledge can also contribute to higher pass rates for equipment training.

Automation Best Practices

Fiber system design and installation is labor-intensive, and costs can mount quickly. That’s why the right automation tools and methodologies for design and construction are necessary for success. The best case is when automation extends from the design, all the way to the permitting process.

The right automated tools can help:

• minimize work duplication between teams to meet cost targets.

• innovate new delivery capabilities where application of resources could drive out cost.

• elevate a process that includes high-powered computer-aided design (CAD) tools or working within a GIS environment. (See Figures 1a and 1b.)

• implement and refine a data collection process via Cloud-based collaboration.

• utilize a graphical network engineering tool that minimizes the amount of data imports and reduces errors.

• apply to all applications, direct buried, below grade, and aerial. (See Figures 2 and 3.)

Figure 3. Aerial application.

For a litany of political, legal, and economic reasons, it may be particularly challenging to successfully permit a construction project in sensitive areas (for example, regions of California). Coupled with a decreased number of resources at the public authority level, it can be more challenging than ever to ensure that a project with the engineering and construction complexity of a fiber optic network deployment can move forward smoothly and easily.

To stack the deck for success, our fiber engineering group created and vetted a template which meets the requirements of the target city construction permit application process. The permitting template establishes a baseline for what is needed to increase automation of this process, and demonstrates an accurate understanding of the municipal requirements. Attributes and layers can be changed as fiber is deployed in different locations. This process allows us to work smarter, not harder. By enabling a more efficient and smoother workflow, we not only reduce our time expenditures, but can also increase our total capabilities and maximize fiber optic network build efficiencies worldwide. Why? Because in this high demand environment, providers need to automate and train a work force that can design and install 40,000 or 60,000 feet of fiber per day.

Where to Go From Here?

Cost-reduction measures continue to shape fiber networks. If costs don’t continue to go down, millions of people will be living in a data dessert. To prevent this, future fiber networks might look very different than today’s deployments. Fiber-to-the-home might appear as we traditionally see it: fiber to an optical network terminal (ONT) on the side of a subscriber’s house. But it could also appear in the form of high data rates on other platforms, such as vectored VDSL, G.fast, hybrid fiber coaxial cable, or even a wireless local loop.

Service providers have a multitude of platforms in their Last Mile tool box. The service provider will choose the high-speed data platform that works best for a particular geographic location.

In any case, automation and a trained work force will be keys to deployment success.

Ericsson is the driving force behind the Networked Society – a world leader in communications technology and services. Our long-term relationships with every major telecom operator in the world allow people, business and society to fulfill their potential and create a more sustainable future. For more information, please email: [email protected] or visit https://www.ericsson.com/ourportfolio/telecom-operators/fiber-network-deployment.

Save