Maintaining a Robust Copper Infrastructure According to Cable Type

When a large number of customers are out of service, there is a root cause. Unfortunately, rather than do the hard work to find that cause, many technicians have been taught to cut to other available, good cable pairs (AKA "cut to clear"). Eventually, when all those pairs are gone, the techs must now double down efforts. That means more personnel on the job, more hours and more expense to go back and repair the faults they didn’t take care of the first time or possibly lay new cable. That also means customers are without service for longer than necessary. Some telephone companies end up with up to 80% of their repair forces working on the effect of old cable problems, rather than finding and fixing the cable fault, or faults, in the first place.

Field technicians should be provided a proven process for analyzing the patterns created when various types of cables fail, for whatever reason, that will lead to the root cause or causes.

They also require patience from management so they can spend the time needed to find and fix faults rather than cut to clear because management is pushing them on to the next job.

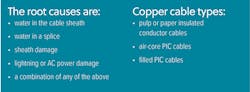

CABLE FAILURES AND TYPES

When a cable fails, testing several cable pairs with a Volt-Ohm-Meter (VOM) will show a pattern of symptoms indicating the type of cable that has failed and the root cause of that failure.

PATTERN OF SYMPTOMS

Pulp and Paper Cable Failures

Pulp and paper cable failures are few compared to PIC cable failures, and usually are completely out of service until found and fixed.

When testing multiple cable pairs, test -25VDC tip and ring to ground; and test from 2k ohm to 50 kohms tip to ring indicates water in pulp or paper cable splices.

Low resistance faults, some pairs shorted or grounded, some pairs test open, some pairs test crossed battery — these indicate sheath damage.

Air-Core PIC Cable Failures

Plastic Insulated Cable (PIC) has a high dielectric strength, and moisture intrusion can take place without immediately affecting service.

It was once thought that PIC technology was the answer to moisture problems, and that the extruded plastic covering would protect the conductor indefinitely even with moisture in the cable, as long as no outside force caused damage.

But experience showed that faults would appear in a wet section after several months of immersion. The reason being most plastic insulation has microscopic air bubbles that are undetected by the spark tester during manufacture.

After water has saturated the cable for a long period of time, the water permeates the plastic at these thin spots and allows current leakage between the conductors and shield.

Whatever the reason for the intrusion, water in PIC shows a pattern of symptoms which, when analyzed, indicate water in a splice or encapsulation, water at the site of sheath damage, or water internally in air-core cable.

Any combination of water and DC battery results in electrolysis (the electrochemical decomposition of metal). If the water is internal, the shield is affected. If the water is in a splice, encapsulation or damage spot, the conductors are affected.

A typical telephone system uses a negative potential of -51 volts on the ring, with the tip conductor at earth-ground. In reference to the ring, this makes both the tip and the earth-ground positive

The tip conductor and earth-ground are of the same potential, so no current flows and no electrolysis occurs between them when water enters the cable. The aluminum shield and the tip conductor are sacrificial (they lose molecules of metal) to the negative ring potential. As dielectric failures on the tip may or may be in the vicinity of the faulted ring, electrolysis is usually confined to decomposition of aluminum shield.

InvisiLight® Solution for Deploying Fiber

April 2, 2022Go to Market Faster. Speed up Network Deployment

April 2, 2022Episode 10: Fiber Optic Closure Specs Explained…

April 1, 2022Food for Thought from Our 2022 ICT Visionaries

April 1, 2022Thus, testing a cable conductor-by-conductor with a VOM would show crossed battery on ring conductors with very few tip faults. The indicated battery would be very low voltage. Testing the isolated shield would show from 15 to 30 volts DC on the shield if there were no sheath damage.

- The symptoms listed earlier confirm that there is water in the cable sheath and no sheath damage.

- Resistance bridge measurements indicate faults at random footages throughout the water.

- Capacitance measurements on a known good pair show the section as longer than the actual length, indicating the amount of water.

- The Time Domain Reflectometer (TDR) analysis indicates the location of the water in the section.

Splice and Encapsulation Failures

Water intrusion into a splice or an encapsulation may happen suddenly, or years could pass before troubles begin and the cause is recognized.

When this occurs, tested faults indicate grounded shorts with crossed battery on both ring and tip.

- Resistance faults between ring and tip are usually in the 270K ohm to 10K ohm range.

- Tip conductors will be "going open" due to electrolysis.

- There usually are plenty of pairs to cut to if the problem is in the underground.

- If the problem is beyond the customer’s drop terminal, the pair is cut off beyond (COB).

- A proven section fault is "cut around" until there is nothing left to cut to, and then PBX or similar wire is laid on top of the ground to bypass the bad section.

- Trouble reports by subscribers indicate: "Cable cut by lawn mower," "Chewed by Pit Bull," and so on.

Sheath Damage

When testing a section, sheath damage has the same indications as a bad splice, except that solid or low-resistance shorts and opens are indicated by the VOM. The process for identifying the trouble site is the same as when locating a bad splice or encapsulation. Damaged cables can go unnoticed for an extended period of time without proper analysis and reporting.

Each customer report, properly analyzed and thoroughly pursued, can eliminate unnecessary cutting. Through proper analysis, the first man on site can determine if the faulted pair is an individual one-pair fault affecting just that customer, or if the fault is part of an eventual cable failure.

Know what is out there. Having a good idea of the physical characteristics, electronic capabilities, and system weaknesses arms the technician with the education and tools to do the primary job: maintain the customer in service. Once a trouble is found and repaired, DC characteristics of the circuit are proven good. On the same dispatch, AC characteristics should be tested for transmission quality, and unacceptable parameters corrected.

Signing off

Call me or e-mail me with any questions or comments about my column. Remember, as my best friend in the business often says: McCarty is not always right. Please stay in touch and let me know if you disagree or if you have more questions. My job is to write columns, to train technicians, to review equipment, and to work with you and your managers to help make you successful. Call or text me at 831.818.3930 or email me at [email protected].

Like this Article?

Subscribe to ISE magazine and start receiving your FREE monthly copy today!

About the Author