Building Up the Bandwidth With Rollable Ribbon Cables —

For years, network operators have had a fundamental decision to make regarding outside plant cable: loose tube or flat ribbon fiber/cable. It was an easy choice. Lower fiber counts used loose tube cables and higher counts used ribbon.

The decision has been mostly driven by cost, with loose tube cable typically advantageous in lower fiber counts, and flat ribbon preferred above counts of 144 to 216 fibers. For higher fiber counts, ribbon cables and splicing are both less expensive, and the larger size and difficulty breaking out individual fibers from ribbons does not typically offset that advantage.

That equation has changed over the past few years as rollable ribbons have made their way into the network. Cables with rollable ribbons can be small, easily handled, and provide safe and easy access to fibers, like loose tube cables. They also enable ribbon splicing, speeding deployment times and helping reduce costs, like traditional flat ribbon cables. Although rollable ribbons were first introduced into high fiber count applications such as data center interconnect networks, they are rapidly being adopted in applications traditionally served by both flat ribbon and loose tube cable types. It is very likely this trend will continue at an even faster rate in the years to come.

This article explores why and how rollable ribbon cables are rapidly becoming the cables of choice for network operators of all types, replacing both flat ribbon and loose tube cables in a variety of applications.

A Buffet of Benefits

The demand for fiber is significantly increasing, with FTTH investment expected to double in the next 5 years, compared to the past 5 years, according to RVA LLC. The general public is beginning to understand what we in the industry have known for a long time, and it is a line coined by the Fiber Broadband Association: If it’s not fiber, it’s not broadband.(1)

Rollable ribbon cables were first used for data center interconnect applications — think very high fiber counts (currently up to 6,912) over relatively short distances. They are still used in those applications, but the application space has significantly broadened to virtually all aspects of the network. The reason is that rollable ribbons bring 2 key advantages to network operators relative to cables with traditional flat ribbons or even loose tube cables, that benefit 3 network applications.

2 Key Advantages

1. Size and Density

In networks, smaller size with higher density is often better.

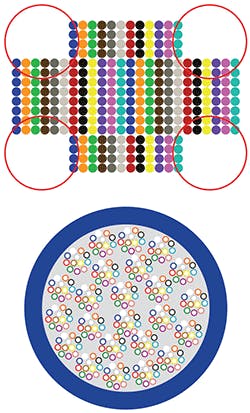

Higher density often comes down to simple geometry. In round cables, circular rollable ribbons are simply more space-efficient than rectangular flat ribbons. (See Figure 1).

For underground cables, smaller, lighter cables fit into smaller ducts and can often be installed in longer lengths than larger, heavier cables. For aerial networks, smaller cables mean less weight on poles and less surface area for ice and wind to accumulate.

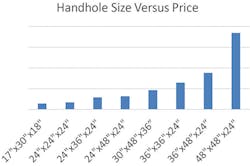

Smaller cables can also use smaller handholes. Handhole size and cost is often an overlooked aspect to network deployment costs. Graphing handhole size versus price reveals what looks like an exponential relationship, which intuitively makes sense since volume is a cubic function. (See Figure 2). Smaller handholes can reduce cost, especially helping reduce costs at the larger sizes.

2. Splicing

The value proposition for ribbon splicing has been understood for more than two decades. It is pretty simple. Splicing 12 ribbon fibers at once is significantly faster than splicing 12 individual fibers, helping to significantly reduce splicing costs and overall installation time.

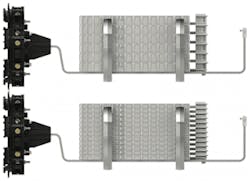

An additional splicing benefit is that the small size of rollable ribbons can enable the use of smaller splice trays, which can mean more trays (and more fibers) in a smaller closure size. A picture of thicker ribbon trays contrasted with thinner trays that can be used with rollable ribbon is in Figure 3. This can be a very important benefit in crowded metro area handholes.

A third splicing benefit, especially important in today’s FTTH distribution networks, is that it is easy to separate out individual fibers during the mid-span access process. This has been a main reason that many service providers have used loose-tube cables in the distribution portion of the FTTH network.

Similarly, it’s easy to access a specific ribbon and fiber in a rollable ribbon cable in mid-span application.

InvisiLight® Solution for Deploying Fiber

April 2, 2022Go to Market Faster. Speed up Network Deployment

April 2, 2022Episode 10: Fiber Optic Closure Specs Explained…

April 1, 2022Food for Thought from Our 2022 ICT Visionaries

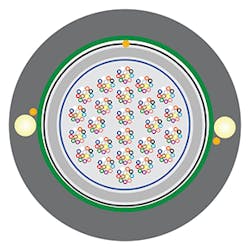

April 1, 2022With rollable ribbons, the individual ribbons are easily identified, as shown in Figure 4. Each ribbon can be handled as a separate unit, much like loose buffer tubes are today. Once the proper ribbon is found, the fiber is easily accessed. Where mid-span access of a flat ribbon could be slow and tricky, especially in inexperienced hands, mid-span access of a rollable ribbon is safe and simple. It is as easy as identifying the fiber and then pulling it out.

3 Network Applications Benefit

Network applications can benefit from these advantages.

1. Central Offices and Data Centers

Central offices and Data Centers have long been crowded with equipment and cabling, meaning that space is a premium. This also means that denser cables can bring significant value in these spaces. In comparison to traditional tight-buffered cables or even indoor flat ribbon cables, rollable ribbon-based premise cables can put more fibers in less space.

For example, Figure 5 shows how 10,800 fibers can fit in a 12"x 8" cable tray using 72 fiber tight buffered cables. Using 72 fiber flat ribbon cables, the number is over 27,000. However, with 72 fiber rollable ribbon cables, over 91,000 fibers can be safely deployed in the same space.

Rollable ribbon cables are now available in a wide variety of premise cable types, including interconnect, backbone, and indoor-outdoor versions, with appropriate flame and smoke ratings.

2. Backbone and Metro/Regional Networks

Both flat ribbon and loose tube cables have long been used in these applications, with ribbon cables used for higher fiber counts. Rollable ribbon cables fit well in these applications due to the various

advantages mentioned above, including smaller size, longer lengths, and ribbon splicing.

3. Distribution Cables

The distribution network is where rollable ribbon cables can bring the biggest new benefits to network operators.

Loose tube cables have been used in fiber-to-the-home backbone distribution applications for years. However, central tube rollable ribbon cables, such as OFS’ AccuRoll™ Rollable Ribbon cable, shown in Figure 6, may be used in place of loose tube cables to combine the benefits of flat ribbon and loose tube in one design. These cables can be smaller than traditional loose tube cables and can be ribbon spliced. Also, unlike central tube flat ribbon cables, the rollable ribbon version of these central tube cables is easily mid-span accessed.

The Rollable Evolution

When first launched, rollable ribbon cables were mainly for ultra-high fiber count applications. Today, service providers are discovering that the benefits of rollable ribbon cables extend throughout the network.

References and Notes

1. "The Public Is Waiting: The Longing for Fiber Is Long Overdue" by Michael C. Render, RVA LLC. May 2021, ISE magazine. https://isemag.com/2021/05/telecom-fiber-network-deployment-trends/

For more information, please email [email protected] or visit https://www.ofsoptics.com/. You can also follow OFS on Twitter @OFS_optics.

Like this Article?

Subscribe to ISE magazine and start receiving your FREE monthly copy today!

More Solutions from OFS:

Webinar Rewind: FTTH Cabling Design with Supply Chain in Mind

3/2/22: Explore options available for FTTH Design and Cabling that can affect all the key elements required to build on schedule and cost effectively.

Video: The Last Hundred Meters: OFS Single Family Drop Systems

Simple as 1,2,3… The InvisiLight® Drop Solution provides a nearly invisible fiber optic solution inside the home and provides confidence that the network will meet the bandwidth demands of tomorrow.

Webinar Rewind: The Final Frontier – The Drop to and in the Home

10/13/21: Learn of the challenges facing service providers with deployment to and in the home and some potential solutions for these challenges.

About the Author

Mark Boxer

Technical Manager, Solutions and Applications Engineering, OFS

Mark Boxer is Technical Manager, Solutions and Applications Engineering, OFS. He has more than 35 years’ experience in fiber. For more information, email [email protected] or visit: www.ofsoptics.com. You can also follow them on Twitter @ofs_optics, LinkedIn: https://www.linkedin.com/company/ofs/, and Facebook: https://www.facebook.com/ofsoptics/.