Are You Meeting These Critical Fiber Deployment Objectives?

Technologies and Tactics to Help

One of the few bright spots that emerged from the pandemic is the recognition of just how critical broadband Internet access is to our everyday lives. It’s hard to imagine what it would have been like over the past year+ without broadband infrastructure in place to support activities like remote learning, work-from-home, and streaming entertainment.

And for those of us in the IT/telecom industry, this acknowledgement is long overdue. The job, however, is far from done.

Recent studies have estimated that between 18 million to 42 million people in the US lack broadband Internet access. Fortunately, initiatives like the Rural Digital Opportunity Fund (RDOF), the recently passed Infrastructure Bill, and others, have earmarked over $85 billion to close this gap.

These ambitious projects will require innovative approaches and new technology development to ensure that broadband service can be rolled out in a timely and cost-effective manner.

And while funds have been allocated for broadband projects, there are other headwinds, such as the well-documented shortage of skilled fiber optic installers, which threaten to slow it down.

Fortunately, there have been a myriad of new developments in the fiber optic industry that make much better use of scarce resources, including labor, that are impeding broadband deployment.

3 Objectives

Here we share 3 objectives service providers aim to achieve along with fiber technologies and their impact through all stages of fiber deployment and activation:

Objective #1: Simplify Fiber Installation

Objective #2: Facilitate Plug-and-Play Connectivity to the Home

Objective #3: Improve Time to Service with Improved Testing Strategies

Objective #1:

Simplify Fiber Installation

Innovative fiber cable designs are significantly smaller than traditional fiber cables. This allows service providers to maximize use of already crowded duct space, and, in some cases, defer the need for additional civil works to add duct banks.

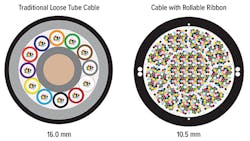

A comparison of traditional loose-tube duct cable with 144 fibers vs duct cable with collapsible ribbon fiber shows a 52% reduction in size. Similar size advantages are seen in higher fiber count cables. One example of this type of fiber cable design is SpiderWeb Ribbon®. (See Figure 1.)

And with continuing improvements in mass fusion splicing and splice-on connector technology, cable installation and termination can achieve the efficiencies needed to support the massive rollout of fiber-to-the-home. The combination of collapsible ribbon fiber and mass-fusion splicing can provide up to an 89% reduction in installation and termination time compared with conventional cable and single-fiber splicing methods.1

Objective #2:

Facilitate Plug-And-Play Connectivity to the Home

With the sheer magnitude of fiber to be installed, terminated, and tested, conventional fiber deployment methods can become a bottleneck. Using pre-terminated cabling greatly speeds up fiber deployment by creating a plug-and-play environment for adding new services and customers.

Hardened single-fiber and MPO connectors, designed to withstand outdoor environments, are becoming commonplace for FTTx and 5G networks. These connectors are terminated in the factory, thus ensuring low loss termination. Examples of a pre-terminated port terminal and single fiber hardened connectorized cable are shown in Figure 2.

As with all fiber connectors, these hardened connectors must be inspected and kept clean to guarantee that the link loss is within acceptable limits. Clean connectors are essential, since additional truck rolls to perform remedial inspection and cleaning can impact fiber activation times.

Advanced digital fiber inspection scopes have on-board pass/fail analysis which provide installers with rapid, objective results, thus minimizing inspection time while taking the guesswork out of deciding whether fiber connectors are clean or dirty. Hardened MPO connectors can be inspected with pass/fail analysis in under 15 seconds, greatly speeding up fiber verification.

Fiber cleaning tools have also been developed specifically for several of the more common hardened fiber connectors.

Objective #3:

Improve Time to Service With Improved Testing Strategies

The shortage of experienced fiber optic installers has driven the need for manufacturers to rethink the design and operation of fiber test equipment. Complex, multi-purpose test equipment is being replaced by intuitive, easy-to-operate, purpose-build instruments that require minimal training for technicians new to the fiber optic industry.

A perfect example of this is fiber testing for PON service activation. Verification of the presence of all required wavelengths is a requisite step in the provisioning of new PON services.

To accomplish this, next-generation PON power meters known as Through-PON Power Meters can test PON networks in both directions, downstream from the OLT (Optical Line Terminal) based in the Central Office, as well as upstream from the Optical Network Unit (ONT) based at the customer premises. (See Figure 3.)

These power meters have the advantage of being able to test in both directions, thus verifying that both the OLT and ONT are delivering sufficient signal power levels. Figure 3 shows how Through-PON power meters can be used at the fiber distribution hub or at the customer premises.

This service activation tool is a critical part in provisioning PON services in a greenfield environment, and in brownfield environments that are migrating from GPON to one of the different types of 10G PON. Many service providers that deployed GPON services in the past are in the process of upgrading their networks to 10G PON, which is needed to deliver the bandwidth that their customers demand.

A well-designed Through-PON power meter detects presence of legacy as well as next-gen PON signals, and correctly establishes power limits based on where in the network testing is performed. For example, downstream power level limits at the customer premises will be lower than power level limits at the distribution hub.

Focus on the Fiber

The importance of the telecom network is only increasing, as most workers continue to follow a hybrid work model. And as many service providers are converging their wireline and wireless networks as part of 5G rollouts, the need for innovation technology to simplify and speed up deployments is becoming more critical. Fortunately, the fiber industry is responding with creative solutions to simplify deployment in all phases, from installation, to termination, to activation.

Resources And Notes1. AFL Internal Study, presented at Fall BICSI Conference 2021.The benefits and costs of broadband expansion

For more information, please email [email protected] or visit https://www.aflglobal.com/Products/Test-and-Inspection.aspx. Follow AFL on: Twitter @AFLglobal, Facebook: AFLcorp, LinkedIn: afl-2, Instagram: photos.afl, and YouTube: AFLglobal.