Fusion Splicing Choices Matter —

Given the size of the US market and the growing demand for data across both fixed and mobile networks, there is continuous pressure for operators to invest in fiber networks to push connectivity closer to the customers. In addition, 5G, Massive IoT and Big Data bring new use cases that require operators increase their investment in FTTx networks.

Fiber is the method of choice for operators because of its scalability, security, and ability to handle the vast amounts of backhaul traffic being generated. It can handle the increased speed demands with lower attenuation and over much longer distances than traditional copper-based technologies like Digital Subscriber Line (DSL) and cable.

Precision Delivers Low Loss

Fiber deployment requires very complex and precise fusion splicing technology to ensure high-quality connections. With such an intricate but necessary function, network operators need to choose fusion splicers carefully as they can affect the quality of the network.

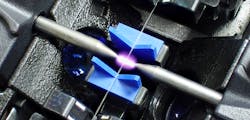

Quite simply, fusion splicing is the method of fusing 2 glass fibers together. It is achieved through heat and precision. Generated by an electric arc, high temperature is applied to 2 glass fiber ends in order to fuse them together.

Due to the extremely high accuracy that is needed, a fusion splicing machine is used. to align the fiber cores and apply the exact amount of heat to melt the ends before pressing them together. Once the fibers are aligned, the splicer fires an electric arc between the 2 ends, which melts them immediately and fuses them into 1 piece of fiber.

InvisiLight® Solution for Deploying Fiber

April 2, 2022Go to Market Faster. Speed up Network Deployment

April 2, 2022Episode 10: Fiber Optic Closure Specs Explained…

April 1, 2022Food for Thought from Our 2022 ICT Visionaries

April 1, 2022Vital to achieve this is the mechanical strength of the fusion splicer as well as its optical insertion loss. Ensuring the splicing occurs in a highly visible environment enables the operator to work closely with the fibers to make an accurate, precise connection for seamless connectivity.

Due to the size and delicate nature of fiber, the practice of fusion splicing can be very challenging. During the process, it is possible for some optical power to be lost due to contamination, environmental stressors, fiber glass breakage or damage. Splicing is successful only when the fusion of 2 fibers connect seamlessly without compromising the fiber optic connection. Therefore, reducing the risks of losing optical power is key to expand connectivity.

During splicing there is a maximum splice loss threshold which, if exceeded, can prohibit the optical circuit from functioning. The ideal splice loss target is <0.05 dB per splice. A high splice loss, over 0.1dB, will compromise the optical power. With very little room for error, the ideal fusion splicer selected for operation must deliver results in that target zone.

To maximize the optical power connection during fusion splicing, the fusion splicer selected for operation must perform with precision, accuracy, and speed. In order to choose the ideal splicer, network providers should ask these 2 questions about the splicer they plan to purchase:

Question 1: How does the alignment system perform?

This is vital role in positioning of the 2 fiber ends for seamless fusing. There are 2 types of alignment methods:

Type 1. Core Alignment

A core-alignment system uses a combination of image and light detection systems that "view" the fiber cores to measure and monitor the core position during the alignment process.

Type 2. Clad Alignment

The clad alignment aligns fibers based on a clad, which is the outer surface of the fiber.

Question 2: Is the arc power stable?

The arc power is integral to the performance output of a fusion splicer machine. If the arc power is too high or too low, the splice position becomes too fat or too thin, which leads to a high splice loss. Using arc calibration, a splicer can achieve the optimum arc power level.

For improved results and for achieving a low splice loss, the splicer should release arc power stability. Under different environmental conditions such as altitude or temperature, the fusion splicer may not be able to release the appropriate level of arc power. This explains why, in the cases of sudden changes in environmental conditions, arc calibration is required to adjust the arc power to fit the changed condition that is present.

It’s Not Optional

Due to the complexity of fiber optic deployments, operators need to consider products and solutions that can be managed with ultimate ease and maximum efficiency. The fusion splicer selected can make or break network connectivity and reliability. For the ultimate level of precision and accuracy, operators should opt for easy-to-use, high-specification solutions that reduce the likelihood of error or optical insertion loss.

Deciding which is the most efficient fusion splicer requires providers to analyze all the mechanical features that can help create the optimum working environment for preventing splice loss and maximizing connectivity.

INNO Instrument America Inc. has revolutionized the deployment of FTTx networks worldwide with its View 8+ premium core-alignment fusion splicer and the VIEW12R-200 mass fusion ribbon splicer to splice 200-micron fibers. (See Figures 1 and 2.) With the future requiring such a drastic change in demands, selecting a fusion splicer that can reduce splicing time to a matter of seconds in a simple and easy way is crucial to the adaption of changes in bandwidth and connectivity demands.

Figure 1. VIEW8+ Core Splicer

Figure 2. VIEW 12R

As the pressure on networks is only going to increase, operators need to consider all options, and remain flexible and ready for any eventualities should they arise. As technological advancements and innovation continues, the pressure on networks is going to mount further, making fusion splicers with easy-handling designs and speedy processes critical to their future.

Preparing for the Unpredictable

Operators are not able to completely future-proof their networks, as it is impossible to know exactly how the environment will change in the next decade and beyond. But selecting a fusion splicer that creates the most user-friendly working environment that enhances productivity and efficiency on site, while meeting the critical requirement of low splice loss connectivity, is crucial to adapt to the changes in bandwidth and connectivity demands.

Like this Article?

Subscribe to ISE magazine and start receiving your FREE monthly copy today!

There are many options for operators to consider when selecting the right fusion splicer for them. But as the pressure on networks is only going to increase, network operators need to take advantage of systems and tools that deliver speed, precision, optimum power, and minimum splice loss, helping them to do their job effectively.

About the Author