Brian Schrand

VP, Applications Engineering

Clearfield

ISE: New technology being introduced allows customers to do the final step of the fiber installs using plug-and-play technologies. Is Clearfield going to be a player in that space?

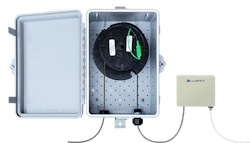

Schrand: The most time-consuming and expensive operation in installing a FTTx network is hooking up the customer. A technician can spend a significant amount of time inside a customer’s premises. Clearfield has responded to service provider requests to offer a solution that allows their subscribers to perform a self-installation. The solution is our Home Deployment Kit (HDK) which comes packaged with everything they need to do a self-install from the demarcation on the house to their network gateway.

ISE: Selecting the right network architecture for your fiber deployment is a major key to your company’s success. Each type has benefits and drawbacks. What’s the best option for your build and business model?

Schrand: Speed of deployment, ROI, cost per home passed, capital and operating expenditures are all factors that broadband service providers (BSPs) take into consideration when choosing their network model. However, network capability is often overlooked. A network’s capability or performance is dependent upon its link loss budget. Keeping loss to a minimum will provide a robust network and extend its longevity. Splitters are the largest contributor to network loss—therefore, it’s important to design a network where you can control the amount of splitter integration.

Home run architecture is the most fiber rich, having a one-to-one fiber ratio from the electronics to the subscriber. It offers the most flexibility but also costs the most to build.

Centralized split is currently the predominant leading PON architecture. The fiber ratio is one fiber from the electronics to a splitter, typically 1x32, in a cabinet with a one-to-one fiber ratio to the subscriber. Centralized flexibility lies in the ability to change the split ratio at the cabinet. Centralized is less costly than home run, but still takes a significant amount of time and capital to construct.

Distributed split is second behind centralized. The fiber ratio is one fiber from the electronics to a multi-layer split, usually 1x8 to 1x4, then to a one-to-one to each subscriber. There is little flexibility for upgrades due to splitters being distributed throughout the network, but in contrast to the previous two, it’s less expensive to build because it eliminates the need for cabinets and requires less splicing labor.

Distributed tap is an optical version of a coax network. The fiber ratio is one fiber from the electronics to optical couplers to splitters. Signal is bled off at each coupler to feed a splitter which then feeds subscribers. It’s a limited, asymmetrical network with no flexibility for upgrades. The benefits are speed to deployment and low capital cost.

ISE: What is Clearfield doing to help push active equipment to the edge of the network to cut down latency and optimize routing capabilities?

Schrand: The exponential growth in bandwidth demands is causing BSPs to evolve their edge and access networks to accommodate 10 Gbps in anticipation of 100 Gbps. This evolution requires actives be pushed out closer to subscribers. In edge networking, regional and demographic considerations create a need for multiple cabinet sizes that are environmentally controlled and accommodate a variety of equipment configurations and fiber terminations. Clearfield recognized BSPs challenges for pushing equipment to the edge and developed the fiber optimized FiberFlex cabinet line. The flexibility of the FiberFlex line addresses all the associated issues BSPs face, for easements, power and environmental. It can be intimidating when choosing cabinet options. Clearfield offers both pre- and post-sales support to assist customers during the entire process.