A Powerful Solution for Conquering Conduit Cable Chaos —

Setting up the PDRP.

When Steve Haus inspects a typical conduit array, inside a typical manhole vault, on a typical jobsite, the number of cable placements found there is anything but typical. In fact, the number can be daunting.

You see, Steve’s typical jobsite can include the Concourse Plaza in the Bronx, or Times Square in Manhattan. Situations such as these are where you are likely to find manhole vaults equipped with dozens of cable conduits (or ducts) deploying a Medusa of cables in all 4 directions.

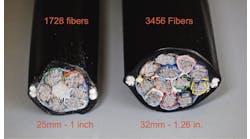

Encompassing over 50 thousand miles of phone, Internet, and CATV cable services, the underground infrastructure network throughout the Greater New York City area is complex. It serves 8.3 million residents, 3.9 million workers, 250,000 businesses, and 50 million annual visitors, according to the NYC Department of Information Technology and Telecommunications.

Bedlam in the Bronx, Mishmash in Manhattan

Fiber optic cable damaged by power snake action.

Managing and maintaining that cable mishmash is the job of Steve Haus, Foreman with the Hellman Electric Corporation, and his crews.

With headquarters in the Bronx, Hellman Electric Corporation is one of New York’s largest utility contractors. As a premier full-service contractor, Hellman installs and maintains outside plant services, heavy construction, corporate interiors, and datacom projects, throughout the metropolitan region.

Replacing nonfunctioning utility cable or installing new cable can be problematic. With a power and telecom cable infrastructure for a city the size of New York and its boroughs, it’s no wonder ducts in underground networks become over crowded. Steve Haus and Hellman Electric had to find a better solution for conquering the conduit cable chaos.

InvisiLight® Solution for Deploying Fiber

April 2, 2022Go to Market Faster. Speed up Network Deployment

April 2, 2022Episode 10: Fiber Optic Closure Specs Explained…

April 1, 2022The PDRP — conquering the conduit cable chaos.

The ideal powered duct rod tool would be engineered to make short work of placing pulling lines or fiber optic cables through old, partially collapsed and crowded ducts, and ducts with multiple route bends. When compared to traditional hand rod wire fishing practices (where more human muscle is necessary), fewer hands would be required as the entire process would be achieved with the use of a powerful hydraulic pump and the push of a lever.

This is important because there are some cable ducts that have multiple bends and they can become overcrowded. As a result, work crews must muscle through during cable placement procedures. "This brute force option is typically used in empty ducts," observed Steve Haus. "If you’re not careful, power rodding can cause damage and destroy existing cabling in crowded ducts — especially fiber optic cables," he added.

A crowded manhole.

"We are working in an ancient system that was never designed for the capacity we are demanding of it, and much of it can never be rebuilt or improved," Haus observed. "For this reason, rodder trucks that we used in the past are now useless for working in urban underground ducts."

Hand Rodding Can Be Counterproductive

To avoid damaging fiber optic and other cables, and for placing pushing or pulling lines, Hellman also relied on fiberglass hand rods. These non-conductive rods are used for guiding (or fishing) wire or cable through ducts, walls, attics, crawl spaces, etc.

These rods come in many configurations, but in street construction they are typically on large reels, in lengths of 300-1,000 feet. Much to Haus’ dismay, they have become the mainstay of Street Fiber. Once needed only on occasion, they are now often the only suitable tool available. Being a working foreman, Steve himself endures the same physical trials as his crew, pushing these rods through multiple ducts on a daily basis.

Typical duct wall — a Medusa of cables.

Over time, this method of hand rodding can become inefficient and counterproductive. One example is the load weight of the rods themselves. "In a crowded or damaged duct, it takes a good bit of muscle to force a fiberglass rod a distance of 300 feet," Haus explained. "And when you do this a dozen times per day, multiple times per week, it can really wear you out."

Haus must also face the kind of duct resistance and roadblocks inherent with old city construction, wherever aging underground technology is still in use. "Working in the underground infrastructure found in the oldest sections of the city can be challenging," said Haus. "When we encounter century-old terra-cotta, iron, concrete, or even ducts made of creosoted wood, chances are good that we will find sections that have collapsed. This requires additional rodding force to clear through the collapsed areas," he added.

Damaged ducts inside a manhole vault.

Newer duct sections can also cause resistance and roadblock problems as well. Collapsed ducts can occur at Point-of-Entry (PoE) locations. PoE demarcation points are shallow installations where manholes and underground ducts are installed closer to street level. This allows the sprawling underground infrastructure routes beneath it to pass along unabated.

PoE ducts are, therefore, more vulnerable to damage due to the wear and tear of heavy street traffic above. "Even the force of a garbage truck dropping a trash dumpster on the pavement can cause a PoE duct beneath it to collapse," said Haus.

PDRP Pushes the Limits of Productivity

Hellman Electric combines power rodding with hand rods (with footage markers) along with poly twine snares (grapple technique). An alternative solution that Hellman Electric employs is the Powered Duct Rod Pusher (PDRP) by GMP. Its maximum performance distance is about 600 feet (in occupied duct), Hellman often deploys traditional hand rodders along with the PDRP rod when working in very long sections.

Brendan Werner of Hellman Electric works inside a New York City manhole.

"We put snares on the PDRP, and then send it in from one side until it stalls out," Haus explained. "Knowing the exact footage, we can then send in a footage-marked hand rod with hooks from the other side to catch the snares on the PDRP."

Once connected, Hellman retracts the hand rod slowly to guide the PDRP forward until it reaches the next manhole. This allows Hellman to tackle precise rodding work and greater distances more efficiently. "While the PDRP setup time takes longer, the rodding portion takes less time when compared to previous rodding methods," Haus explained.

"When we were hand rodding, our performance degraded quickly beyond 300 feet of duct," Haus recalled. "Now, we can push or pull well beyond that distance and in less time. For example, on City Island in the Bronx, we were rodding 1,200 to 1,300 feet using this method."

Haus likes the adaptability and convenience of the PDRPs. The unit’s overall size allows him to deploy and operate in tight work environments. "Another advantage is that these units will fit on many of the truck configurations in Hellman’s fleet," he said.

The PDRPs can also be powered by the hydraulic tool circuits on Hellman trucks, and not necessarily by the dedicated, hydraulic power packs alone. Still, Steve Haus is finding alternative uses for the power packs.

Like this Article?

Subscribe to ISE magazine and start receiving your FREE monthly copy today!

One example is running hydraulic trash pumps on vehicles without hydraulic tool circuits. Because many manholes are full of water when first opened, they need to be pumped out before Hellman’s crews can begin working in them. The power packs provide a valuable added benefit in that regard.

The underground infrastructure network throughout the Greater New York City area is certainly intricate, but Hellman Electric has found ways to bring some order to the chaos.

About the Company: For more than 80 years, General Machine Products (KT), LLC, a subsidiary of Klein Tools, has been recognized as a premier global supplier of a wide range of products for the telecommunications, power utility and cable television industries, and the contractors who serve them. Product applications include the placement of fiber optic, copper conductor, and coaxial cable both aerially and underground.